Your cooktop: Playing field and experimental area in one

Fits induction, gas, electric, and your cooking style

Compatibility. For your creativity

With a SCHOTT CERAN® cooktop, many think I only cook with electric. But regardless of whether you prefer an electric, gas or modern induction cooktop: SCHOTT CERAN® glass-ceramic fits everywhere and is the perfect basis for your way of cooking.

EXPLORE ALL HEATING TECHNOLOGIES

For everything that may happen on your cooking surface

SCHOTT CERAN Miradur®

Your kitchen is not a showroom, but a living space. Full of action, sometimes hectic, and sometimes something goes wrong. Thanks to the scratch-resistant SCHOTT CERAN Miradur® coating, your glass-ceramic cooking surface remains flawless and you stay relaxed.

Almost as hard as a diamond

In addition to pots and pans, there are also completely different things on the cooking surface: salt grains from seasoning, and sand grains from vegetable cleaning or a shopping bag. All these might leave scratches. But not with Miradur®. Thanks to a special coating, it has a scratch resistance similar to the hardest gemstones.

As beautiful as on the first day

Miradur® is 95%* more scratch-resistant against sand than conventional cooktops. It also offers protection in the event of another, rather unexpected danger: cleaning. An abrasive cloth can cause micro-scratches. But Miradur® is also 70%* more scratch-resistant against abrasive sponges. This gives you a flawless glass-ceramic surface and many years of enjoyment. (*According to PI test.)

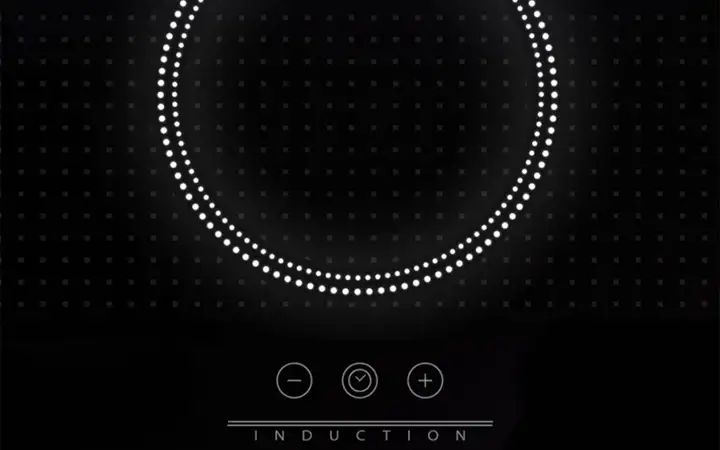

The new glass-ceramic is this smart: SCHOTT CERAN Luminoir®

SCHOTT CERAN® has been part of the kitchens of this world for 50 years. Now comes the completely newly developed smart glass-ceramic: SCHOTT CERAN Luminoir® is deep black and more translucent than ever before. This opens up almost endless possibilities for design and intuitive operation. Together with the sophisticated black look, your kitchen will become a place of experience more than ever before. True black. Bright light. Pure joy.

Bring light and ambience to your kitchen with CERAN EXCITE®

SCHOTT CERAN® – Excitement on top

More than cooking: A real experience

SCHOTT CERAN® transforms functionality into emotionality. Material, design, and light appeal to the senses. The cooking surface is an entire world: for inspiration, for communication, for a special experience. More than 200 million customers have already opted for it. Especially because cooking becomes such a pleasant experience with SCHOTT CERAN®.

DISCOVER MORE ABOUT THE BRAND